SENKO pellet stoves are used for heating residential spaces and/or as central heating and at the same time they can be a decorative element in every ambience. They are designed and produced down to the last detail in order to satisfy, in the best way possible, all consumers’ requirements regarding functionality and safety.

Tangential (cross-flow) fans are blowing warm air from the stove to the room through special grids on the front side of the stove. The second fan is leading the primary air to the firebox and at the same time flue gases are lead from the firebox to the chimney. Dosing of pellets to the firebox is automated and programmed with an electronic switch by means of a screw feeder.

The firebox is equipped with a door with fire-resistant glass (up to 700°C) thus achieving a nice visual effect of flame within the firebox and at the same time ash and smoke are prevented to exit to the heated space. The inner part of the firebox is produced from vermiculite – a self-cleaning resistant material securing high heat capacity. The external sides of the stove are produced from stainless steel or dyed as requested with heat-resistant high quality powder.

The pellet stoves have the option to be regulated by remote control and/or mobile phone. They also have the option of programming the daily / weekly work schedule of the stove (6 available option – for e.g. if you are working till 16 h (respectively you are not at home) you may programme the stove to heat at 18°C from 06-16 h, and from 16-22 h at 24°C and the like). In case of an unexpected situation, safety devices are activated, which are automatically stopping the pellets dosing to the firebox and reporting the alarm signal on the control panel.

SENKO pellet stoves are distinguished by their high efficiency (91 – 96 %) as well as a very low environmental pollution level. They are constructed by means of most modern software and technologies in accordance with all safety measures stipulated by Norm EN 14785. By taking care of every component of the stove the protection of both the user and the installer from possible accidents is secured.

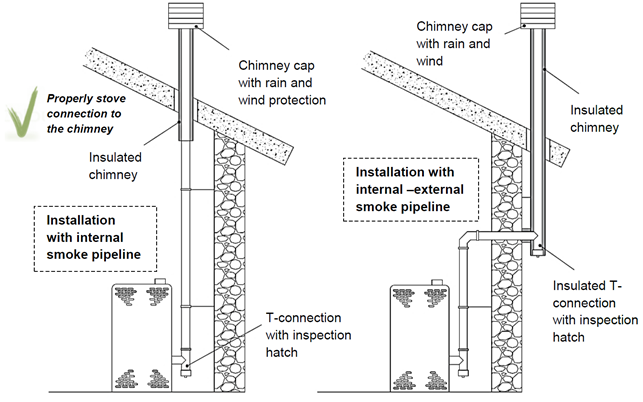

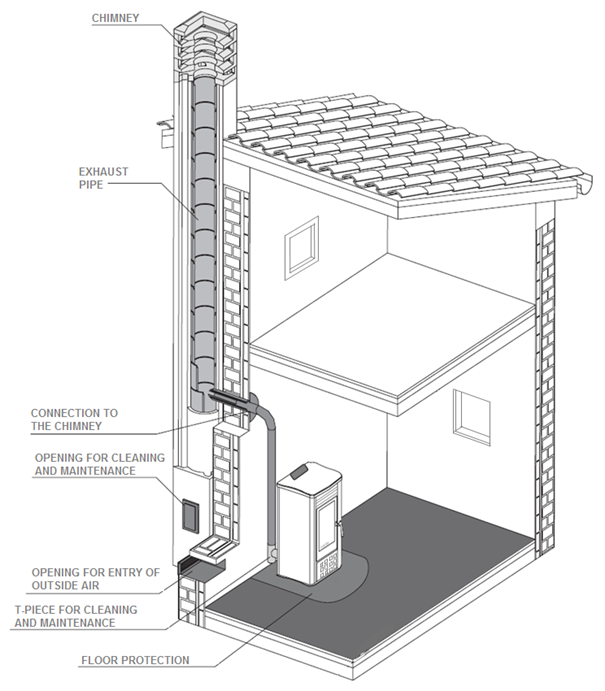

CONNECTION TO THE CHIMNEY

If you want to achieve the declared power of the stove with the accompanying pellets consumption, it is necessary to connect the pellet stove to a functioning chimney.

The chimney must be of circular cross-section and with an exhaust pipe lid for protection from wind and atmospheric conditions (rain, snow, leaves and the like).

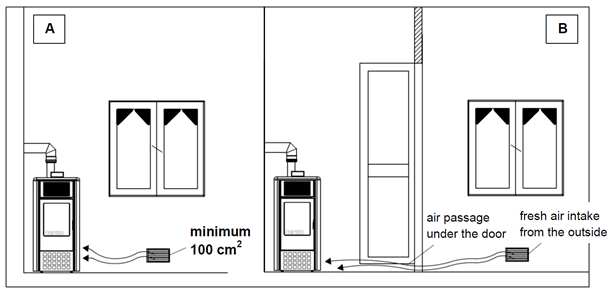

The next obligatory condition for the correct operation of the stove is the supply of fresh air to the room in which the stove is positioned. The surface of the opening for fresh air supply cannot be smaller than 100 cm2.

The opening must be carried out in such a way that it cannot be blocked in any way whatsoever (protected with a grid, metal net or a similar appropriate protection).

The air can also be brought from neighbouring rooms, it is important that these rooms are constantly without hindrance supplied with outside air.

For a proper combustion of pellets a sufficient underpressure in the chimney (10-14 Pa), depending on the stove power, is also required. The chimney will achieve the underpressure solely if it is well isolated and if it has a functioning exhaust pipe lid with a protection from wind. The isolated chimney prevents the cooling of flue gases whose temperature is within limits between 65 and 200°C (depending on the stove power). A poorly insulated chimney has a too low underpressure (less draught) and the most often consequence is the black glass on the firebox door and, in case of low outside temperatures, a total blockage of the firebox with no possibility for the pellets to burn which ultimately creates an exceptionally dangerous situation for the stove user. There is also a problem in case of too high underpressure of the chimney which is the result of a too big chimney diameter. You can recognise a too strong combustion by the big and noisy flame, the temperature of flue gases rises above 240°C and the consequence can be a deformed firebox.

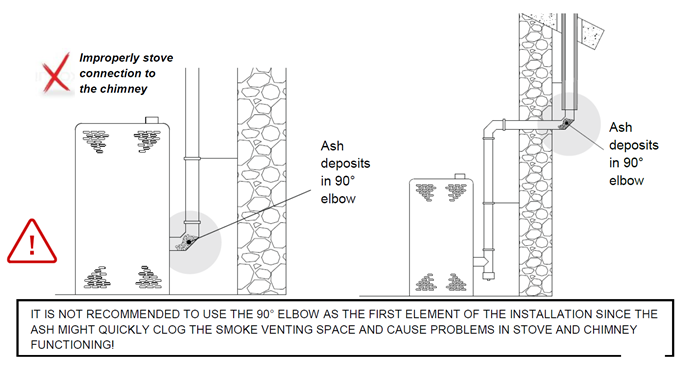

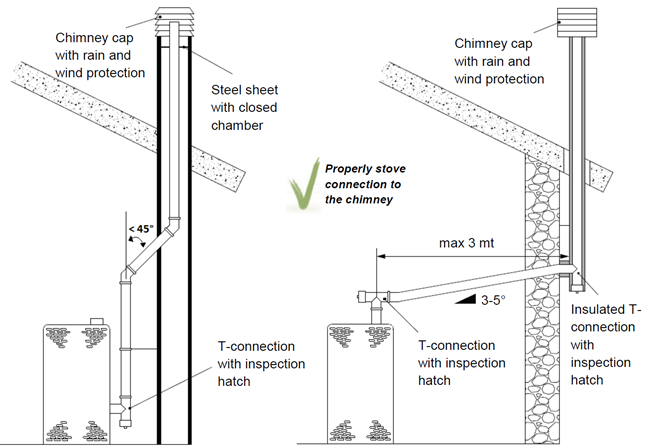

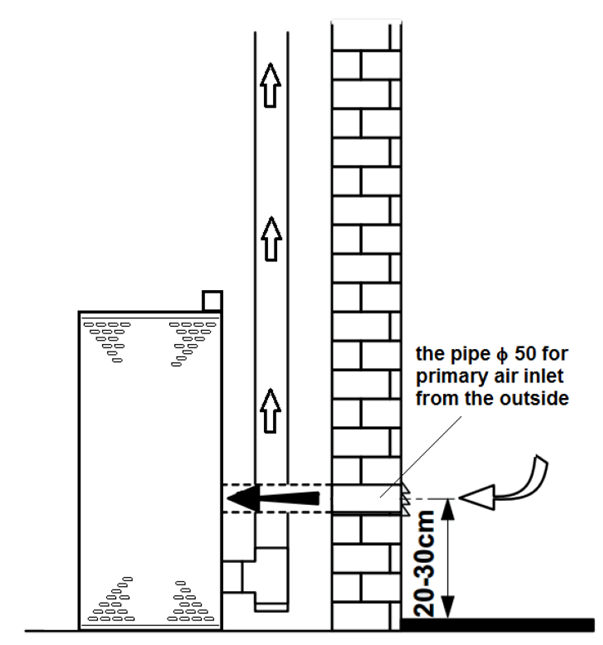

The stove is connected to the chimney with exhaust pipes with a minimal diameter Φ 80 mm (length of pipes up to 3 m), OR Φ 100 mm (length of pipes more than 3m). That length is calculated by adding the parts of the horizontal pipe and the vertical pipe ones, at the same time taking into consideration that every pipe elbow of 90° corresponds with one linear meter. The installation of horizontal parts must be avoided as much as possible.

WHEN CONNECTING THE STOVE TO THE CHIMNEY, FOLLOW THE FOLLOWING INSTRUCTIONS :

- horizontal parts must have an inclination of minimum 3° upwards,

- the length of the horizontal part must be minimal and in any case not longer than 3 m,

- the number of pipe elbows (inclination 90°) cannot be higher than 4 (including the T-piece) – in case you require more than 4 pipe elbows, use a pipe with an inner diameter of Φ 120 mm,

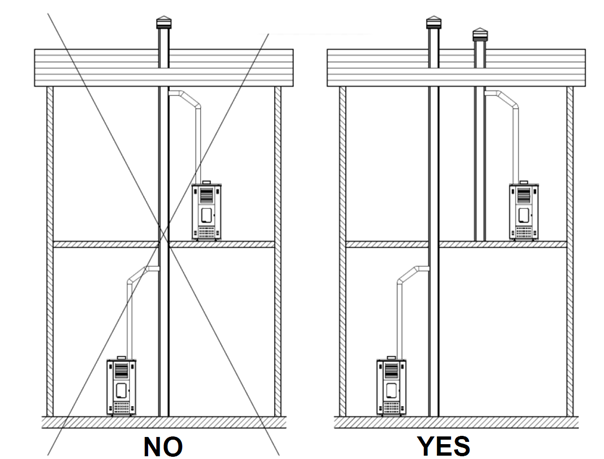

- the chimney must never be carried out by means of wall breakthrough (through the façade) but it must be carried out through the roof in order to secure normal combustion!

English

English  Deutsch

Deutsch  Hrvatski

Hrvatski  Magyar

Magyar  Română

Română  Slovenščina

Slovenščina