An external combustion air supply is mounted at the rear side of the cooker to avoid consumption of hot air (oxygen) inside the rooms used for living (mandatory for low-energy and passive houses). The lack of oxygen in the room causes significant health problems in humans.

An external combustion air supply is mounted at the rear side of the cooker to avoid consumption of hot air (oxygen) inside the rooms used for living (mandatory for low-energy and passive houses). The lack of oxygen in the room causes significant health problems in humans.

SENKO cookers are coated with chamotte, to maximally use all generated heat, which results in lower fuel consumption for equal heating of the room.

SENKO cookers are coated with chamotte, to maximally use all generated heat, which results in lower fuel consumption for equal heating of the room.

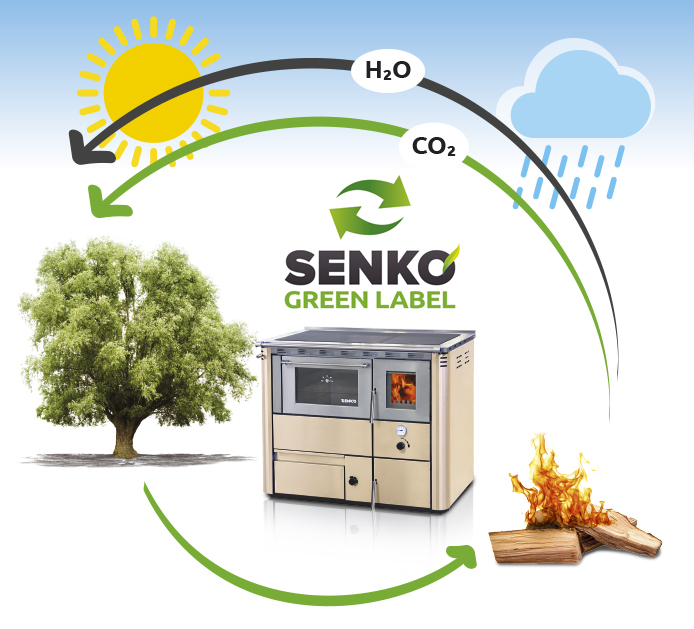

Construction solutions and intake of secondary air into the firebox provide an additional fuel efficiency and combustion of harmful gases. In this way SENKO cookers fully comply with environmental standards and enable wood burning process described by the SENKO GREEN LABEL.

Construction solutions and intake of secondary air into the firebox provide an additional fuel efficiency and combustion of harmful gases. In this way SENKO cookers fully comply with environmental standards and enable wood burning process described by the SENKO GREEN LABEL.

To change the grate’s summer/winter position during firing, cookers for central heating offer thread driven firebox grate - to achieve the maximum cooker performance.

To change the grate’s summer/winter position during firing, cookers for central heating offer thread driven firebox grate - to achieve the maximum cooker performance.

All models are equipped with glass firebox door to enable control of fuel combustion.

All models are equipped with glass firebox door to enable control of fuel combustion.

Chimney/Flue connection is height adjustable to facilitate easier installation of the cooker.

Chimney/Flue connection is height adjustable to facilitate easier installation of the cooker.

Cooking plates are made in thickness of 8 mm – warping and cracking is avoided (longer lasting operational life of the cooker).

Cooking plates are made in thickness of 8 mm – warping and cracking is avoided (longer lasting operational life of the cooker).

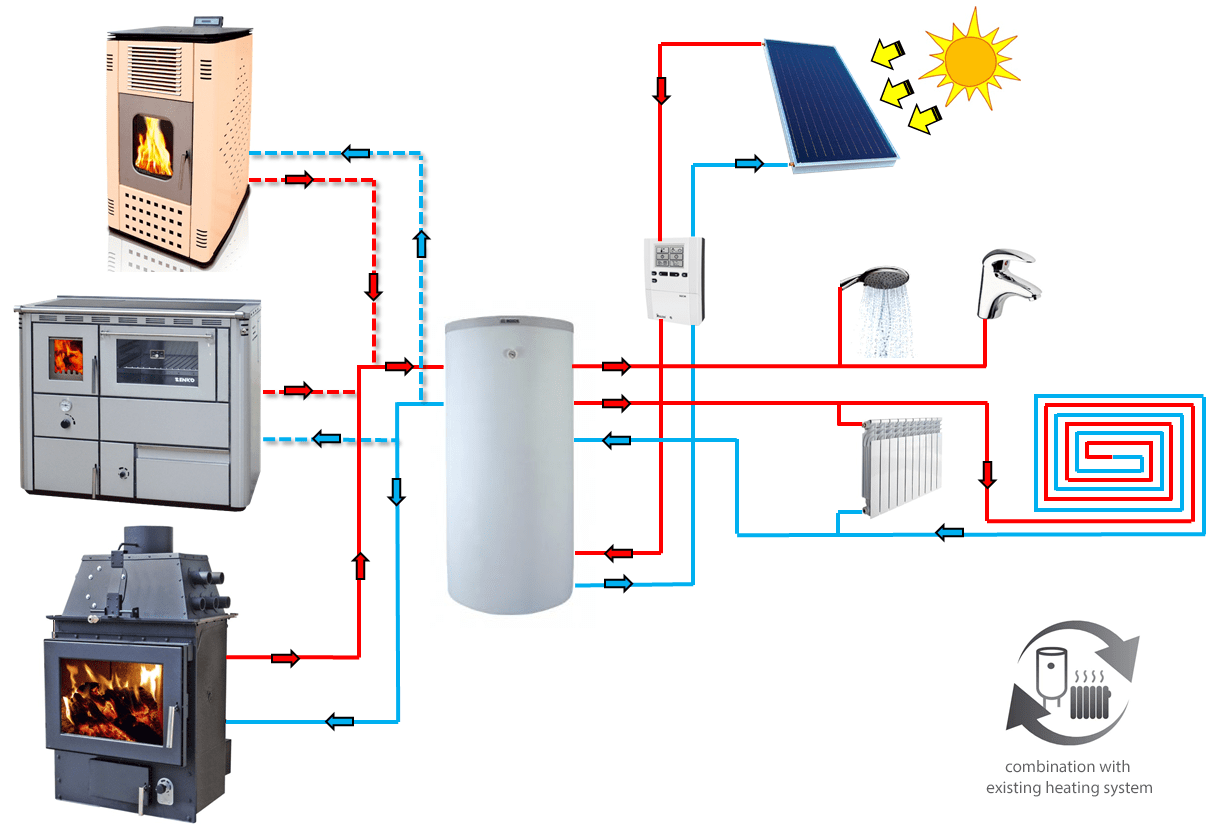

Senko products can be mounted as a part of your already existing central heating system (gas, heating oil or solar energy), so you can change to the cheaper fuel for your central heating at any point and save money.

Green part of SENKO cookers

By photosynthesis of water, earthy minerals and carbon dioxide (CO2), with the help of sun energy, grows the tree. During combustion, heat, water, CO2 and minerals (ash) are released. Wood is stored sun energy!

Thanks to this cycle of overgrow, the wood is completely environmentally friendly fuel. SENKO cookers fully meet the environmental standards and are ideal for fuel combustion in this energy cycle.

English

English  Deutsch

Deutsch  Hrvatski

Hrvatski  Magyar

Magyar  Română

Română  Slovenščina

Slovenščina